Timeline 29 June to 21 September 2014

This is a continuation of the work done to Sasha.

I continue to clean up round the fresh air vent on the drivers’ side, this is going to need some repair work. It takes me quite a while to get the fresh air vent off as the screws are rusted in, I end up cutting them off with the grinder, this has the effect of melting the plastic of the vent, but I eventually get it off without too much damage. I get the whole area cleaned up with a wire brush in the grinder.

You can see the extent of the rust in the picture.

Thursday, 3 July 2014

This evening I have some time so I decide to clean up some parts, the clutch slave cylinder gets washed off in petrol, cleaned up with a wire brush in the bench grinder. The fittings on the hose and bolts and washers are cleaned up as well, although I might replace the bolts and washers with stainless steel.

This part is the shield that goes over the fuel lines at the bottom of the bulkhead, this had been the source of a constant rattle. There was only one nut holding it to Sasha, I have had quite a time getting hold of replacements. It turns out that the same nuts are also used to hold the heat shield for the CAT and exhaust in place. I eventually managed to get some from Mini Sport. I degrease the shield and clean it up with a wire brush in the bench grinder.

Saturday, 5 July 2014

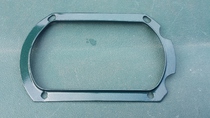

I don’t generally work on Sasha stuff on a Saturday as I usually reserve this day for spending time with my wife Frances and jobs round the house, but with the house jobs complete I work on some chrome pieces that we picked up from Darren. The original items from Sasha are too badly rusted to re-use so thanks Darren. I clean and polish the headlamp rings and headlamp retaining ring using a polishing mop and compound in my old Bosch drill, I must get the adapter so I can use the polishing mops on my bench grinder.

I make a plate to repair the drivers’ side fresh air vent, I start with a piece of cornflake packet and cut to size with scissors. I then transfer the pattern to metal and cut it out, I then mark where the holes need to be then drill out the 4 small holes for the plastic vent mounted in the inner wing and cut the larger hole by drilling a hole large enough to insert the jigsaw blade, then cut the large centre hole with the jigsaw. I test fit the plastic face vent, then with the plastic vent out of the way I weld on some captive nuts ready for final fitting.

I test fit the panel, make any adjustments, hold it in place with my magnetic welding clamp, then tack it in place.

Saturday, 12 July 2014

Another Saturday when I am able to do some work on Sasha’s parts, today I started with the remote gear change. I stripped off the gear stick, fixed bar and the mounting bracket, I then thoroughly cleaned the rest of the assembly in petrol. After that I cleaned everything with a wire brush in my bench grinder.

Rust has gotten between the flitch panel and the hinge stiffening panel in a couple of places, the easiest way to repair this is to cut out the rusty area and weld in some new metal. To make this job a bit easier and because the A panel is starting to go, we decide to remove the A panel.

The A panel had been replaced before so I cut through the A panel all the way down with a cutting disk, where the A panel meets the sill I cut very carefully with the cutting disk to release the bottom of the A panel. I was then able to grind through the welds holding the A panel to the flitch panel very carefully trying the preserve the flitch panel as much as possible.

With the A panel out of the way I cut out the bubbles of rust with my rotary tool with a cutting disc in it, make up a couple of patches and weld them in. The larger hole at the bottom I will repair later.

While I am here I decide to remove the A panel on the passenger side as well, once I start cutting it off I find that it is worse than the drivers’ side, so it was a good idea to replace them.

There is a little bit of repair work needed round the fresh air vent, this is taken care of by just welding the holes up, trying to be careful not to melt the fresh air vent.

I clean off any loose bits with a wire brush in the grinder, only minor bits need to be sorted.

With the top edge of the bulkhead cleaned off I have treated it with some zinc weld through primer ready for fitting the new scuttle panel when it arrives. I have found in my experience that the weld through primer works will when spot welding but my MIG welder spits really bad trying to go through it, so if I am going to MIG weld I generally leave bare metal and if I am going to spot weld I will use the zinc weld through primer. I have tried the copper based version of weld trough primer but this is no better, I think it might actually be slightly worse.

Time to clean up the workshop, lock up and make our way home, we will be away from the workshop for a while as we are off on holiday to Florida.

While I have been working on the top dash rail Abi has been doing some cleaning up inside Sasha and on the bulkhead under the bonnet. Unfortunately she has uncovered another horror, in the form off more tin worm in the inner sill on the passenger side. At first glance before Abi got a hold of it I thought I might be able to patch it up. No it’s gone too far it will have to be replaced.

Sunday, 31 August 2014

My first job today is to clean up the inside of the car around the drivers’ side fresh air vent, where I cut away some rust the closing piece on the A post is no longer connected to the inner wing so before I treat the area with etch primer I just put some tacks on it to keep it in the correct place.

Now it’s time to put a major piece back into Sasha, it’ seems like so long ago that she was a whole car, it will be nice to start putting bits back in rather than continuing to cut on her.

I user some self locking pliers to hold the top dash rail in the correct position, it does take me some time and a number of test fits before I get to a position where I am happy to start welding.

Sunday, 7 September 2014

Today we spend almost all day trying to get the scuttle panel to fit properly, if I just put it in place and centre it it is about 5mm short each side. I try various things to get it to fit better including trimming more off the windscreen pillar. I eventually get it to fit ok by starting on the passenger side and using lots of clamps to hold it in the correct position, then pushing it down towards the drivers’ side, clamping it where I can and easing it into the right position. I did try starting from the drivers’ side and pushing it over to the passenger side but it just would not sit in the correct place.

Abi says I am procrastinating too much and should just weld it in.

Saturday, 13 September 2014

We usually work on Sasha on Sundays but as it is the Mini show at Stanford Hall tomorrow we decide to come and work on Sasha today.

Continuing with the scuttle panel today we decide to check alignment with the bonnet before we go past the point of no return. Happy that the bonnet fits ok with the scuttle panel in place it is time to start spot welding it into place.

Now with the spot welding complete on the passenger side the job looks quite good. All I have left to do is to MIG weld the joint on the windscreen pillar on both sides and MIG weld the scuttle panel to the top of the inner wing.

Enough for today time to get home, see what bargains and parts we can pick up at Stanford Hall tomorrow.

Over the space of the week a little gap has opened up between the scuttle panel, bulkhead and top dash rail, this is where I didn’t manage to spot weld it. I couldn’t get the spot welder in because of the windscreen vents, so I decide to clamp it drill two holes in it them plug weld it with the MIG welder, this will give this area a bit more strength. Any excess weld is taken off with the grinder.

At this point we decide to do a test fit of the wings and A panels, we did put the bonnet back on as well but didn’t take a picture with that in place. Everything fits back together quite well, once the front panel arrives that will take care of the spacing of the inner wings, they seem to have pulled together a bit, but this is to be expected.

While I have been doing all this Abi has been out in the barn cleaning parts that have been taken off, she has been cleaning mainly the ventilation pipes and the plastic parts. All these parts end up in her bedroom much to the disgust of her step mother Frances, but Abi doesn’t want them getting dirty again. I can’t think of many 16 year old girls that have half a car stored in their bedroom.

Last job for today is to repeat the process for the scuttle panel closing panel on the passenger side. As I said these are pattern parts but they actually fit reasonably well, I am quite pleased with this job.

Enough for today, time to clean up all the mess we have made, lockup and make our way home.