Timeline 15 March to 17 May 2015

This is a continuation of the work done to Sasha.

Sunday, 15 March 2015

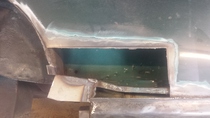

I start today’s work off by cleaning up the area around the Drivers’ side rear sub frame mount by the rear quarter panel, this area is quite rusty. I clean off all the old sealer with the wire brush in the grinder and I also use the wire brush in the die grinder in the more difficult to reach areas. From this picture you can see the extent of the rust damage.

Abi has been cleaning off some of the loose bits along the sill and she have found some damage caused when the over sills were fitted, whoever did it left some deep grinder tracks in the floor and some of them have gone all the way through. I weld over these with the MIG to fill them in again, then run the grinder over them to tidy them up.

The stiffening piece round the proper jacking put has rusted very thin and as there is no standard jack for this car I decide to help preserve the sills I will weld a plate over the jacking point. So I grind off the old stiffening piece with is just spot welded on and clean up the area ready to put a patch over it.

Sunday, 29 March 2015

Today I start by marking out where I am going to fit the repair piece into the rear quarter, I cut down the replacement panel to the size I need, place it on top of the original panel and mark it out. Then using the wire brush I strip off the paint and filler down to bare metal where I am going to cut out and weld. Then I re-mark where I need to cut the quarter panel.

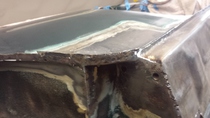

I them weld up between the tacks and grind back the welds to try and get a good finish, I am also trying very hard not to warp the panel. I fail in this and warp the panel a bit I should be able to beat the worst of it out before filling the rest later. I also spot weld the joint with the sill, and clean that up as well.

After some messing about and adjusting I spot weld this seam together and tidy it up with the grinder and wire brush. I also make up a small repair patch to fix a bit of the wheel arch, I shape it as best as I can on the bench clamp it into place, tack it in a bit, adjust it, spot weld it on the wheel arch seam, them MIG it into place. Clean up the area with grinding disc then wire brush, this opens up some more rust that I will need to repair.

But that will have to wait until next week, time to clean up now and get off home.

Friday, 3 April 2015

I continue today with repairing the inner wheel arch, in the past I have tried to do this with one piece of metal but it never bends into the correct shape without puckering because of the complex curves, so I always do this repair by putting in a number of smaller patches about 10cm to 12cm, adjusting the shape for a good fit in the bench before welding them into place with the spot welding and the MIG welder.

I make up the last patch and fit it into the wheel arch, with the MIG welder I patch up the lip of the wheel arch on the outside, then grind off the excess weld leaving it looking much like it did originally, I am quite pleased with the result. I also MIG over some more areas where the metal is a bit thin or has been burnt away by the spot welder.

Sunday, 12 April 2015

I decide to take a break from cutting, welding and grinding. I rebuild the front hubs instead, firstly I install all four new ball joints. I don’t like the job of shimming up new ball joints it take forever, keep tightening it down checking it, pulling it apart again, changing the shims and putting it back together again. Once they are all setup I grease them using a grease gun to fill them with grease until it comes out.

Next task is to fit the new wheel bearings, I start by using a copper drift to drift the new bearing seats into place. Then I pack the new bearings with grease, and hold them in place using the new oil seals, bear in mind that the oils seal with the extra lip on it goes at the back to hold the dust shield in place.

Well all that took longer than I expected and I have run out time for today, I put away all the tools, clean up and make my way home.

I hold the patch in place with a clamp, I also hold the patch in place with the long handled screwdriver while I get some tacks on it. With it tacked in place I can hammer the patch into a bit better shape and finish off welding it into place. I then grind off the excess weld and clean up with the wire brush.

I clean up the passenger side rear quarter panel at the bottom where there is some rust, the corner by the bottom of the wheel arch is like Swiss cheese and the closing panel behind it has all but rusted away.

I have run out of time today so I will start repair to this section next time, for now I clean up the workshop and put everything away, lockup and make my way home.

Like the other side the jacking point needs to be plated over, this will stop any more water getting into the sill and as it has over sills on it the water can’t get out again so it has been sitting in there rusting everything away. I grind off the old stiffening piece from round the jacking point and prepare the surrounding area to weld the patch in place.

While cleaning up the floor and investigating any loose bits I find some damage under the seat cross member, I clean up both areas and make two patches up ready to weld over them. I hold the first one in place with the long handled screwdriver and get some tacks on it. With the patch hammered into place I finish welding all the way round it, I grind off the excess weld and clean up with the wire brush.

Next I make a start cutting the rusty section out of the passenger side rear quarter panel, I use the rotary tool with a cutting disc, at this point I don’t want to remove too much material, I just want to take enough out so I can get to the closing piece to repair that before I get ready to fit the rear quarter panel repair section. With the sections cut out of the quarter panel you can see that there is very little left of the closing piece.

I them cut off a little bit more to give me better access to make up a repair patch for the closing panel.

While I am here I will try and remove the broken bolt from the sub frame mounting point, I have been spraying WD40 into this for weeks hoping to free it up. The first step is to drill a hole through the broken off bolt, this needs to be as close to the center of the bolt as possible. With a 3mm hole through the center I open this out to 4mm, I then try and use a screw in type stud extractor, this is not successful all it does is tighten and it starts to move the captive nut, I remove the stud extractor and apply some heat with the blow lamp, when I have it starting to glow I spray on more WD40 hoping it will penetrate a bit more with the heat. I screw in the stud extractor again and tighten it in, the broken stud still doesn’t move it just starts to me the captive nut again, not wanting to break off the captive nut I give up in favor of an alternate method. I open the hole through the bolt to 7mm the using a tap with the correct thread, I slowly and carefully run the tap through the hole, this cuts new threads through the hole. To make sure the threads are good I run one of the original bolts through the new threads. While I have goo access to all these bolt holes I run the tap through all of the to clean out the threads ready to refit the sub frame at a later stage.

I make up a patch the replace the closing piece that goes under the corner of the rear quarter panel, taking some time to make it fit the best I can, I grind some of the old panel away to get a getter fit, I also grind some off the end of the heal board. Now I have quite a good fit I am ready to start to weld it in place, looks like I will be doing that next week as I have run out of time today.

I put all the tools away, clean up the workshop, lockup and make my way home.

Sunday, 17 May 2015

We took a weekend off last weekend and went to Himley Hall to pick up some parts, I had arranged for Mini Sport to bring a rear sub frame so I didn’t have to pay carriage, it was quite a good show and we did meet up with Darren and Julia in Lue. We picked up a few parts and the new rear sub frame.

I begin working on welding the repair patch into place along one edge, then along the top which is inside the rear storage pocket.

As you can see from the picture I have marked out and cut some more out of the rear quarter panel.

I cut the rear quarter panel out to the guide lines with the rotary tool with a cutting disc in it, after a number of test fits and some more trimming I am about ready to start welding the repair panel in place. In this picture you can see I am using the magnetic welding clamp to hold the panel in place.